Accelerator Pump Jet

Here's a case of "if it ain't broke, don't fix it". I had my Dellorto system on the shelf for about 6 years due to emissions regulations. I then decided to put it back on since the car is no longer a daily driver and I wanted to race it in Autocross. The carburetor was very clean because I had stored it in a plastic bag to keep the dust and grunge out. Being curious I started to inspect the carburetor by removing some of the jets to look for varnish an any other signs of wear. Everything was spotless so I put it on the car.

After completing the installation, the car started right up. So far so good. However, if I quickly (or normally) depressed the accelerator, the car would choke and die. This happened every time. If I very slowly depressed the accelerator, the engine would gradually increase in RPM all the way to red-line. I figured that it wasn't getting enough gas when pressing the gas pedal. Sure enough, that's what was happening. Here's were our friend the Pump Jet comes in.

The Pump Jet meters the flow of fuel from the accelerator pump directly into the throttle bores. I needed to see if gas was squirting when the throttle moved without having to remove the carburetor. I removed one of the Pump Jets and hit the throttle. Sure enough gas shot out of the little hole and down into the bore.

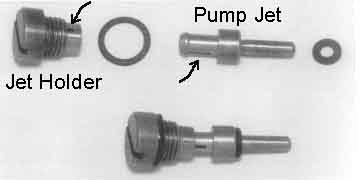

I started inspecting the Pump Jet to see if there was some kind of blockage. There wasn't any. The Pump Jet has a flat spot that matches with flat area in the carburetor body, so it can only go in one way. In the photograph below, you can see a slot in the Pump Jet. When inserted into the body, that slot lines up with the fuel supply hole (for lack of a better term). Now look at the Jet Holder. The Holder screws into the body and is what holds the Pump Jet in place. Notice that there is a hole in the Holder. Since the Jet sits inside of the Holder, the hole in the Holder MUST LINE UP EXACTLY with the hole in the body! When lined up, fuel flows out the hole in the body, through the hole in the Holder, then through the slot in the Jet, and finally down the Jet and into the throttle bore.

If the O-ring and/or washer are compressed or deformed (this happens over time), then the Jet Holder must be turned further, in order to get it tight enough to hold everything in place. If that happens then the hole won't line up and fuel flow will be blocked! This is why the engine was dying when I hit the accelerator. The throttle opened up which allowed a large amount of air to flow into the engine but there was no fuel coming out of the Pump Jets. This caused an extremely lean condition which killed the motor.

To fix this, I had to locate a rebuild kit to get new O-rings and washers. I purchased a rebuild kit from CB Performance and the O-ring was slightly fuller than the old one, but the new washer was actually thinner than the original. I was expecting a bigger washer. In any case, I ended up stacking both washers together and using the new O-rings to get the holes to align, while under sufficient torque to hold everything in place.

There's one other tip. The Holders have vertical marks on them which I assume are supposed to mark the location of the hole. One of mine did not line up so I had to use a Sharpie to mark the location. I then carefully tightened the Holder until the marks lined up with a ridge on the body that has the fuel passageway.

This is definitely one part that you should not remove or loosen unless you have to, and you have new parts for a rebuild.